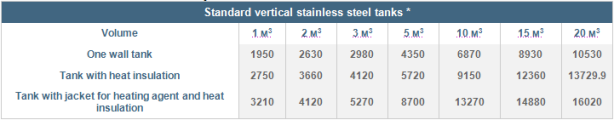

Price-list

*The prices are given in EURO, without VAT

*Prices for tanks of bigger volume, of another type are given on your enquiry.

Standard tank version includes the following: material AISI 304 (“stainless steel for food industry”) with surface 2B (“mate mirror”) flanged conical bottoms, adjustable legs, upper manhole with hinged cover and silicone gasket, sprayball, air vent, technological nozzles and nozzles for control devices according to customer’s order. Coil-spiral or coil piped heating/cooling jacket inside the tank (“Dimple jacket”), all-welded isolation hose.

Accessories (on request of the customer):

· Horizontal tanks: manufacturing and erection works

· Mixing device with gear motor made in Italy, Spain, Germany with double gasketing of the

agitator’s shaft by viton sealing ring , with frame, three-bladed or multilevel bladed agitator

· Supporting legs with adjusting screws and supporting footsteps

· Manufacturing tanks of AISI 321 or AISI 316 steel

· Manufacturing of pressure tanks to 1.6 MPa

· Side manhole of inside or outside opening with silicone gasket;

· Supporting legs with tensometers;

· Level transmitter (with glass or acryl pipe);

· I nspection glasses with or without lighting, with or without windshield wipers;

· Sampling valve in standard and aseptic version;

· Keofit sampling valve;

· Niob sampling valve;

· Rotating sprayball;

· «Endress+Hauser» level transmitter;

· «Klay» Netherlands» level transmitter

· Deltapilot Endress+Hauser pressure transmitter;

· WIKA pressure transmitter;

· «Klay» Netherlands pressure transmitter;

· Bottom valve (butterfly valve or ball valve);

· M&S safety valve;

· Niob safety valve;

·Niob two-way valve;

· Anti-vacuum valve;

· Framed agitator with scrubs;

· SEW EURODRIVE GmbH gear motors;

· Frequency regulator of agitator’s rotations for gear motor;

· Mixing device with high-speed milling agiator and electric motor (dissolver);

· Explosion-proof version of electric motor;

· Side agitator;

· Framed agitator;

· Double front gasketing of the shaft;

· Lower support of the shaft with agitators;

· Service platform on the upper bottom with railings;

· Ladder for tanks with height more than 3 m;

· Contact and non-contact sensors for opening/closing of the manholes;

· Manufacturing of the cube tanks